Test equipment refers to products that are utilized to measure the chemical parameters of coolant, such as concentration, hardness level, and pH.

Zebra Refractometers

Concentration refers to the amount of coolant concentrate in a given amount of water. Customers will get the maximum value from their metalworking fluids when the concentration is held within the proper range recommended by the coolant manufacturer for each process and material.

Brix Scale

Zebra’s Basic and Specialist Refractometers both take accurate readings of concentration, using an optical scale called Brix. Each refractometer is offered in two ranges of scale. To determine which scale range is best for the coolant being used, first verify the coolant’s target concentration and whether it has a refractometer factor. You need this data to be able to read the target value as well as any higher values that may occur due to evaporation.

For instance, a coolant with a refractometer factor of 1 will correspond exactly to the Brix Scale. A target concentration of 7% will read 7 Brix (7% ÷ 1 factor = 7 Brix). A low range scale, such as 0-10 Brix, will only read concentration values up to 10% for this coolant. A higher range scale, such as 0-32 Brix would be more suitable, since it can read values up to 32% for this coolant.

By comparison, a coolant with substantial refractometer factor, such as 2, at the same 7% concentration will read 3.5 Brix (7% ÷ 2 factor = 3.5 Brix). A low range scale, like the 0-10 Brix, will measure concentration values up to 20% for this coolant (20% ÷ 2 = 10 Brix).

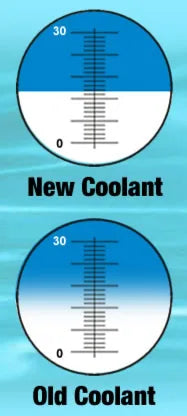

These optical scales may also be used to estimate the level of emulsified tramp oil within a particular coolant batch. For instance, when a sample of newly mixed coolant is placed on the refractometer’s lens, the optical prism inside the refractometer reflects a very sharp line, showing two distinct colors (white and another color). This line will become blurry over time as the coolant ages. The blurriness is caused by emulsified tramp oil, which has been beaten into the base fluid, providing less definite reflection. Machine shop operators who wear contact lenses understand this effect very well, as throughout the day, shop mist blurs them. When you can no longer see any distinct difference between the color values, there is no way to judge where the line exists, and thus what the concentration is. At this point, it is time to change out the coolant in this tank.

Zebra recommends a Basic Refractometer for each machine, or machine cell operator so they can take a concentration measurement during their shift and log the measurement on their Coolant Quality Log. The Specialist Refractometer is very precise, and is recommended for engineering, quality, or maintenance personnel who oversee the general maintenance of coolants used in their shop.

Zebra Hardness Testing Sticks

Zebra’s Hardness Testing Sticks are a convenient and economical way of measuring the hardness value of the initial water source used to mix coolant, as well as measuring the hardness value of a coolant in use, which may change due to evaporation.

Dip the testing stick into the water or the de-oiled coolant sample for approximately 3 seconds, then compare the color value of the stick to the color chart on the package to determine the hardness value.

It’s that easy!

One package of strips will last about a year per sump, since hardness should be monitored once a week. Customers in regions known for having hard water may wish to monitor hardness more frequently to prevent its negative effects.

Some coolant suppliers offer lab testing services to measure the amount of dissolved solids within a coolant sample. In our experience, the advantage of this method over paper strips is nominal, at least for routine monitoring of each sump.

Zebra pH Testing Strips

Zebra’s pH Testing Strips are also convenient and economical. Dip the stick into the de-oiled coolant sample for approximately 1 minute then compare it to the color chart provided.

You may be familiar with the pH strips used to measure the pH of water in a swimming pool. These are not recommended for use with coolant because they do not offer the accuracy needed to monitor coolants which need to be held in a very narrow pH range. Zebra’s pH Testing Strips offer this accuracy, measuring the precise value required to best warn when coolant is showing signs of bacterial contamination and possible chemical breakdown.

Electronic pH Testers are another method used to monitor pH and are very useful in clean, controlled conditions. They are much more expensive than paper strips and require daily calibration, but provide fast and accurate readings. However, because most of our customers do not work in controlled conditions and have not historically been pleased with them, we no longer either offer them nor recommend them for the average shop.

Testing a coolant’s pH value provides the earliest warning signal for bacterial contamination versus the traditional approach of bacterial culture. A culture relies on growing enough bacteria to be visible to the naked eye. A population of 8 bacteria can multiply into 1,032,000,000 in 12 hours, and a visible colony is composed of at least 2 billion bacteria! By the time the results are in, bacteria in the sump have already multiplied to the trillions and it may be too late to take any action.