Zebra offers two types of mixing technology.

Our Machinist Venturi Mixers and Economy Mixers use a venturi. The Zebra Proportioning Pump, on the other hand, uses positive displacement to provide the coolant-to-water ratio. All use water pressure as their energy source.

Venturi Mixers: Zebra Machinist Mixer & Zebra Economy Mixer

When the diameter of a fluid or airline is reduced, the fluid’s or air’s speed increases as it travels through this smaller opening. The increase in speed creates an area of lower pressure allowing for a second fluid, second air flow, or even solids to be introduced into the same stream.

This concept was discovered in 1797 by an Italian physicist, Giovanni Battista Venturi. Today, many types of flow equipment, from oxygen ventilators to bulk solids transport systems, use a venturi.

How Venturi Mixers Work

Zebra’s Machinist Mixer and Economy Mixer use the incoming water pressure to create this vacuum inside their mixing chambers to suction concentrate, and introduce it into the fluid stream. Both mixers rely on this energy for suction purposes, so can deliver the mixed fluid through only a short length of hose. A longer delivery hose forces the energy of the incoming water pressure to push that longer column of fluid, reducing suction capacity, thus reducing mixing capability.

Mixed fluid delivery must also be to open air, so it is not recommended to hard plumb the mixed fluid line. It is also important to use venturi mixers within their water pressure specifications, hard-plumbing the water line whenever possible.

The Machinist Mixer, as discussed in module 121, uses a dial to raise or lower its needle valve. The needle valve controls the orifice size, thus the amount of concentrate, and thus the mixing ratio. The Economy Mixer utilizes various sized orifices, or inserts, which are inserted into the mixing chamber to control the mixing ratio.

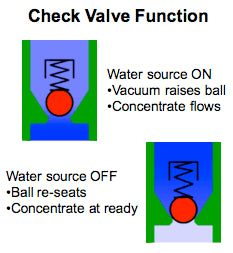

Both mixers have check valves on the end of their concentrate intake pipes or hoses. The valve opens when the water source is on, allowing concentrate through to the mixing chamber. When the water source is turned off, it closes to retain concentrate in its intake so it is “at the ready” for the next use. When this valve is not working properly, it will allow concentrate to drain back into the container. At the next use of the mixing unit, it will again take a minimal amount of time for the suction pipe or hose to fill with concentrate to provide an accurate concentration output per the setting on the unit.

To summarize, mixing units based on the physics of a venturi work well for applications where short-distance fluid delivery is adequate, when installed properly per the unit’s specifications.

Positive Displacement Mixers: Zebra Proportioning Pump

The Zebra Proportioning Pump, by comparison, can proportion and pump mixed fluid over longer distances as well as vertically. This type of mixing unit is more expensive than venturi mixers. However, most operations realize a timely return on investment since the Proportioning Pump reduces labor by providing mixed fluid near the point of use. The Proportioning Pump takes advantage of the physics of positive displacement, using a reciprocating piston.

How Positive Displacement Mixers Work

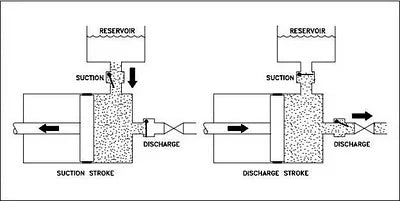

As illustrated below, the incoming water pressure moves a piston forward, opening a valve allowing concentrate to be suctioned. When the piston shuttles back to its original position, this valve closes, allowing the suctioned fluid (and water) to be dispensed through another valve on the output side. The volume is constant for each cycle of operation, or stroke.

This action not only provides the most accurately mixed fluid, but also the ability to pump it long distances. The Proportioning Pump is necessary for users who wish to deliver the fluid closer to the point-of-use, either through a garden hose or via plumbing.

The Zebra Proportioning Pump has a graduated, linear scale (0-9, or 10 lines) on which the length of the stroke is set, corresponding to the output concentration. The concentrate’s viscosity will determine where on this scale the stroke should be set. This means that the scale is not calibrated and the numbers on the scale are not a direct reflection of output concentration.

To determine the location of the setting, first know the mixing range the pump offers. Then find the scale’s incremental value based upon the pump’s range. Then adjust the scale per this incremental value relative to your desired concentration. Check the actual output using a refractometer, and re-adjust as necessary. For example, if the pump’s range is 1.4 – 12.3%, and there are 10 lines, then each line represents 1.09% per line. If your desired concentration is 5%, then you should set the scale at 4.5. Of course, your coolant’s refractometer correction factor also plays a part, but we aren’t considering it here. Always check the actual output using a refractometer.

Installation and Use Options

The proportioner allows for the water source to remain on at all times. It is activated by a decrease in pressure on its output side. So, for instance, a garden hose fitted with a ball valve can be installed on the outlet side. When fluid is needed, the user opens the ball valve, fluid is dispensed (decreasing the pressure), and the pump’s piston begins shuttling again until the ball valve is closed.

Whenever the water source will remain on, and/or the mixer will be delivering the mixture vertically, a back flow check valve, installed on the outlet side of the proportioning pump, will eliminate mixed fluid traveling back into the pump. A back flow check valve may also be installed on the water line to eliminate mixed fluid or concentrate traveling into the water supply.

For all proportioning pump installations, we recommend our water filter, which protects the pump’s small internal components from wear caused by scale. A water limiter is also recommended whenever the incoming water pressure is near the maximum specification allowed by the pump. This will eliminate cracking the pump’s components that cannot withstand very high pressure.

To summarize, mixing units based upon the physics of positive displacement work well for long-distance, manual-control applications.

Automation Options

Zebra is proud to offer the Dazzle automated mixing and delivery system, which utilizes the Proportioning Pump, and its aforementioned accessories, to automatically deliver mixed fluid to receiving tank(s), eliminating manual intervention. We will discuss this product in more detail in the Advanced Level.